- Aa

- Aa

- Aa

Southwest Jiaotong University&Sichuan OST Slope Protection Engineering Co. Completed the World's First in Situ Full Foot Impact Protection Test

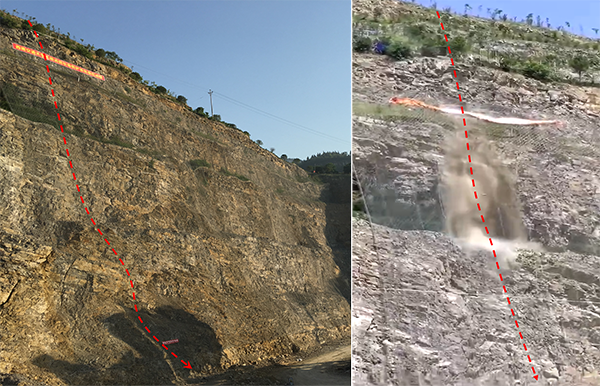

In-situ test of high level rockfall impact protection was carried out in Fuling District, Chongqing by Protection Structure Research Center of college of Civil Engineering, Southwest Jiaotong University and Sichuan OSTS Slope Protection Engineering Co., LTD.

The height of the mountain is 85 meters and the slope is 75 degrees. According to the site conditions, the test block is lifted into place by forklift truck and rolled down the slope naturally. Four times of tests are carried out.

Test objectives:

1. The protective performance of active energy dissipation guide net is tested.

2. Field test data are collected to support the research and analysis of active energy dissipation guide net.

High rockfall impact has the characteristics of high impact energy and great damage effect, especially in the mountain and valley areas in western China. The hidden danger of high rockfall is common and widely distributed, which poses a huge threat to the land pipelines and hydro power development in the transportation cities and towns. Effective prevention and control of it has always been a technical problem in the field of geological disaster prevention and control.

After nearly ten years of research and development, Protection Structure Research Center of Southwest Jiaotong University has obtained many theoretical and technical standards and product development and application results for structural protection technology. The new guided high rockfall flexible protection system adopted in this test is the latest achievement jointly developed by the center and OSTS. Based on the integration of passive and active protection technology, the center put forward the original theory of guide and protection for the first time, and developed a distributed multilevel energy dissipation guide structure system. Different from the existing flexible protection technology, when the new system is subjected to strong impact, based on “active control” and combined with special structural technical measures, the high rockfall is intercepted, suppressed, guided and collected, so as to realize the integration of interception, guide and auxiliary cleaning functions. It is reported that, in order to verify the new technology, the center and OSTS made a bold attempt to conduct in-situ verification test in 2018 in combination with a large-scale blasting project of clearing danger in a mountainous area in Guizhou. The test results show that the system can realize the comprehensive protection energy consumption of more than 100,000KJ due to the advanced distributed energy consumption and guide control technology. Compared with the traditional protection structure system, the protective ability is improved by two orders of magnitude and can be recycled.

In order to carry out the test smoothly, Protection Structure Research Center of Southwest Jiaotong University and OSTS prepared for nearly a year, and completed site selection, simulation analysis, design and manufacturing installation successively. The total number of participants exceeded 30. The test model is installed on a steep slope with a height of 85 meters and a slope of about 75 degrees. It is only supported by 14 steel columns and covers a protective area of more than 10,000 square meters.

In order to obtain test data, three drones, three high-speed cameras, several high-definition cameras and dozens of mechanical sensors and data acquisition instruments were used in the test. At 10 o’clock, the impact test began. Large impact blocks of varying weight are released from a steep cliff with a height of 85 meters, which rolls off at high speed and drives a large number of broken rock mass impact systems. After system interception and suppression, it accumulates to the bottom of slope. Under the condition of no repair of the system, the test was repeated for many times, and the working conditions of single, multi-body group and multi-body following impact were verified respectively.

In the weight of the test block was 0.62 tons. Due to the impact suppression and energy dissipation effect of the guide net, the rockfall moves downward to stop accumulating on the gentle slope platform about 60 meters away.

In the second test, the weight of the test block was 1.1 tons. The rockfall used in the test was deformed, and there was a big crack in the surface steel plate. When the rockfall moved downward to about 25 meters, the crack hung on the wire rope and stopped falling.

In the third test, the weight of the test block was 2.2 tons. During the falling process, the rockfall hit the 1.1 ton test block hanging on the wire rope in the second time. The two rockfalls fell simultaneously, and the 2.2 ton test block moved to the bottom at a slow speed. Due to lack of kinetic energy, the 1.1 ton test block stopped and accumulated in the same gently slope platform as the first 0.62 tons test block.

In the fourth test, the weight of the test block was 3 tons. Under the action of interception, suppression and collision of the guide net, the rockfall moved to the foot of slope at a relatively slow speed.

As a flexible protective product with control and guidance as the main protection concept, active energy-dissipating guide net has high engineering application value. This test has achieved the world's large-scale full-size impact test of the guided high rockfall flexible protection system, and realized the continuous impact resistance of the protection system in the state of no repair, which is a breakthrough in the field of flexible protection structure. On the basis of long-term research, Protection Structure Research Center of Southwest Jiaotong University and OSTS made the decision to carry out the full scale test, so as to further study and analyze the dynamic mechanism of active energy-dissipating guide net system and establish a comprehensive theoretical test method for the design of active energy-dissipating guide net, which provides the foundation for the establishment of inspection and testing specifications (standards) of active energy-dissipating guide net.